BIOGAS UPGRADING UNITS

SRP GREENTECH manufactures systems that are compact and fully automatic for minimum human intervention.

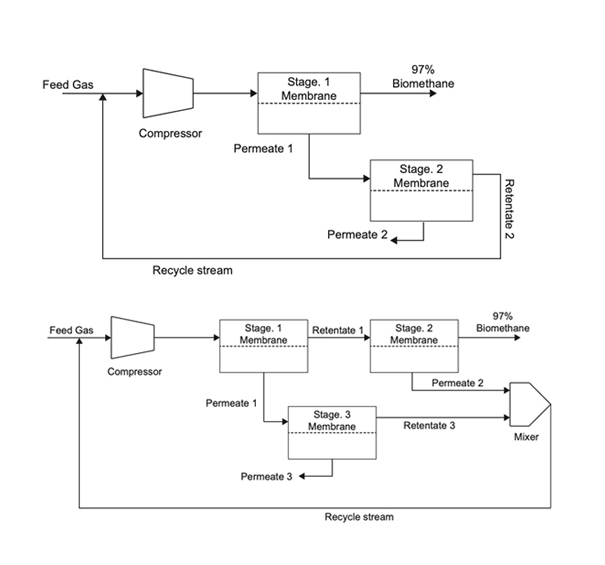

By balancing flow rates and temperature, we as engineered system providers configure the membrane arrays in a way that optimises performance and cost as per individual customer requirement.

FEATURES

SRP GREENTECH manufactures systems that are compact and fully automatic for minimum human intervention.

- Can be designed for all type of Biogas flows from 20 to 10000 m3/hr.

- Wide range of applications.

- CH4, CO2 and O2 concentration analysers.

- Heat Recovery Unit.

- Incoming and outgoing flow monitoring.

- Gas odorization.

- H2S removal as per varied feedstocks.

- Pre-filters to comply with ISO ISO 8573-1: 2010 Class 1.5.1, to ensure maximum membrane life.

- Can be tweaked and designed as per variable inlet and outlet gas composition.

- Structurally sound – built in ISO shipping Containers

- Plug and Play system can be commissioned by just one button.

- Remote monitoring possible.

- PLC Based and fully automatic systems.

- Data Logging

- Gas outlet at pipeline pressure of 16 Bar.

- Guarantee and free Operational Support.

TURNKEY ANAEROBIC SYSTEMS

SRP GREENTECH provides turnkey solutions for biomethanation plants, where we conduct comprehensive feasibility studies of feedstock and provide customers with suggestions to optimise and maximise their investments.

TURNKEY SOLUTIONS FOR ANAEROBIC DIGESTIONS – BIOCNG AND BIO-POWER

SRP GREENTECH provides turnkey solutions for biomethanation plants, where we conduct comprehensive feasibility studies of feedstock and provide customers with suggestions to optimise and maximise their investments. Further, we do detailed design and engineering of the complete project with our team of experienced in-house engineers where in a design report and drawings, specifically for a customer and an application are prepared for utmost customers satisfaction. has over 30 years of experience in executing environmental control projects and construction of various structures. The execution is taken up right from the Civil, electro-mechanical phase to commissioning and to handholding for obtaining necessary NOCs for smooth operation. We also take up operation and maintenance contracts providing the customers with a complete solution. With our self developed membrane based upgrading solutions we are able to provide the customers with the most techno commercially compliant solution for various applications.